|

中文a

Special rotor balance process

METERS

for Balancer

LARGE FAN ROTER END DRIVE

BALANCER

Universal BALANCER

YFW-16000

YFW-10000

YFW-3000

YFW-300

YYQ-160

YYW-30

RYQ-5 |

|

How to determine a

reasonable balancing accuracy

With the development of modern industry, the

precision of rotating machinery and high speed, making the

elimination of machine vibration are becoming increasingly

important. For rotating machinery (such as motors, blowers, diesel,

cars, aircraft), its rotating parts (the following industry practice

by balancing machine, referred to as the rotor) will directly affect

the vibration of the machine's efficiency, life and personal safety.

The unbalance of rotating machinery vibration is one of the main.

Therefore, in order to effectively address the problem of machine

vibration on rotating body (hereinafter referred to as the rotor) is

essential for balancing school testing process measures.

Balancing machine in the rapidly growing

popularity in recent years, use more widely. Its main functions are:

to detect and display the size of the rotor unbalance and location,

to guide the operator will try to remove the unbalance to balance

the rotor precision.

Rotor imbalance, simply put, is due to deviation

from the center of rotor rotation of the rotor geometric centerline.

The rotor rotates the resulting centrifugal force together with the

rotor rotation, the rotor and the rotor in order to stimulate the

installed base (such as: bearing, frame, chassis, body, etc.) to

vibrate. Therefore, it can be said: The main function is to balance

the machine detects the rotor geometric center of gravity of the

rotor centerline offset.

Any kind of instrument accuracy of product will

have its limits, balancing machine is no exception.

Currently, most of balancing machine-made, the

measurement accuracy in the micron level, while the highest domestic

level of the most common machining times to stay in microns (silk,

Road) level, that is, balancing machine accuracy is much higher than

normal machining accuracy can be achieved.

Here are my company's series of hard bearing

horizontal balancing machine of precision and general machining the

rotor corresponds to the most accurate:

|

Maximum

load balancing machine (kg) |

3.5—16 |

50—2000 |

3000—20000 |

|

Limits

of precision balancing machines ( µm) |

0.3—0.5 |

0.5—1 |

2 |

|

Rotor

machining precision (

µm) |

3—10 |

5—20 |

20

or more

|

From the foregoing, there is

no need to balance each rotor balancing machines are the limits of

accuracy.

For different rotor, how to

choose the best balance between a reasonable accuracy of it?

Balancing machine

measurement system to accurately measure the small amount of

imbalance. And this accuracy is usually much higher than the user's

balance is always accuracy.

Accuracy in determining the

balance of the rotor, in addition to special experiments, each rotor

is not necessary to have a balance to the limit of accuracy.

According to the

characteristics of different types of mechanical and practical

experience, the following table lists the International Organization

for Standardization issued a "typical rigid rotor balancing accuracy

level."

|

Accuracy

Grade

G |

eω

(mm

/ sec) |

rotor type example

|

|

G630 |

630 |

marine diesel engine installed in rigid

crankshaft-driven pieces; rigid installation of large

four-stroke engine crankshaft-driven pieces. |

|

G250 |

250 |

high-speed four-cylinder diesel engine

installed in rigid crankshaft-driven pieces. |

|

G100 |

100 |

six-cylinder and multi-cylinder diesel

engine crankshaft-driven pieces. Cars, trucks and

locomotives used (gasoline, diesel) engine machine. |

|

G40 |

40 |

car wheels, hoop wheel, the wheel as a

whole; car, truck and locomotive engine crankshaft-driven

pieces. |

|

G16 |

16 |

mill, agricultural machinery parts; cars,

trucks and locomotives used (gasoline, diesel) engines of

individual parts. |

|

G6.3 |

6.3 |

seagoing vessel (merchant) host worm

drive gear; centrifuge, pump impeller; fan; aero gas turbine

rotor parts; flywheel; general machine parts; normal motor

rotor; special requirements of the individual parts of the

engine. |

|

G2.5 |

2.5 |

gas and steam turbines, including marine

vessels (merchant) rigidity of the main turbine generator

turbine rotor; turbine turbocharger: the machine-driven

pieces; special requirements of medium and large rotor;

small rotor; turbo pump. |

|

G1 |

1 |

tape recorder and record player-driven

pieces; grinding machine driven piece; special requirements

of small armature. |

|

G0.4 |

0.4 |

precision grinding spindles, wheels and

armature, gyroscopes. |

Note:

When the rotor balancing accuracy than G2.5 must be a self-drive or

very close to the actual working conditions of drivers, supporting

balanced way, be possible to get a better balancing.

The user can on the table,

according to their specific circumstances rotor, a reasonable choice

of balancing accuracy.

For example: general

blowers, fans, pumps and other products of the rotor Optional G6.3

level. And so on.

Choosing the appropriate

balance between accuracy, it shall the indicators (such as G6.3

level) are translated into operational a specific target (eg: in a

radius less than the number of grams).

The following details the

calculation method for the user.

Balance precision conversion

method

Assuming the rotor weight W;

The actual operating speed

of rotor n,

That the

actual work the angular velocity ω =

2×π×n/60

or ω ≈ n/10;

If the

accuracy of rotor balancing selection 6.3, which e×ω

= 6.3 mm / sec.

Then, the

rotor allows the center of gravity offset e ≈ 6.3×10000

/ n (micron)

By the

formula e ×W

= m× r

deduced:

Weight

specified in the rotor surface radius of the specified maximum

allowable unbalance m = e × W

/ r

The above equation:

e - the focus of the rotor

correction plane offset (microns μm),

Or known than the unbalance

(g.mm / kg)

m-rotor correction plane

radius r on the quality of the imbalance, grams (g)

r - to where the unbalanced

mass m radius, millimeter (mm)

W - rotor mass, kilograms

(kg)

Operator to the target as

long as the balance of the rotor m or less, can be considered to

balance the rotor has been precision.

Simplified formula: permissible residual unbalance mass (g) = 9549 × total

mass of the rotor (kg) × equilibrium

level (G ... ...) / {actual work speed (rev / min) ×effect

is the radius (mm)}.

For example, a motor rotor:

Total mass = 50 (kg)

Select G6.3 balance grade

level

Actual operating speed for

the 4-pole motor = 1450 (r / min)

Efficiency is the radius =

130 (mm)

Then,

allow the quality of the residual unbalance = 9549×50×6.3

/ (1450 ×130)

= 15.96 (g)

For surface labeling

problem:

There is no uniform labeling

standards. Generally can be labeled as: balancing accuracy: XXX

grams mm (g.mm) or XXX grams cm (g.cm).

Some drawings are marked as:

G2.5--1000 rev / min, while in the drawings to provide the total

mass of the rotor.

The most convenient way to

mark the implementation of the operator is: specify the rotor to

mark its re-location allows the residual imbalance in the

corresponding quality. Such as: "In the face of R200 mm radius XXX

on the quality of the residual unbalance is less than 5 grams.

How to detect

and determine the balance machine and balancing accuracy

What is dynamic

balancing

How to make a

reasonable balancing accuracy

Our balanced

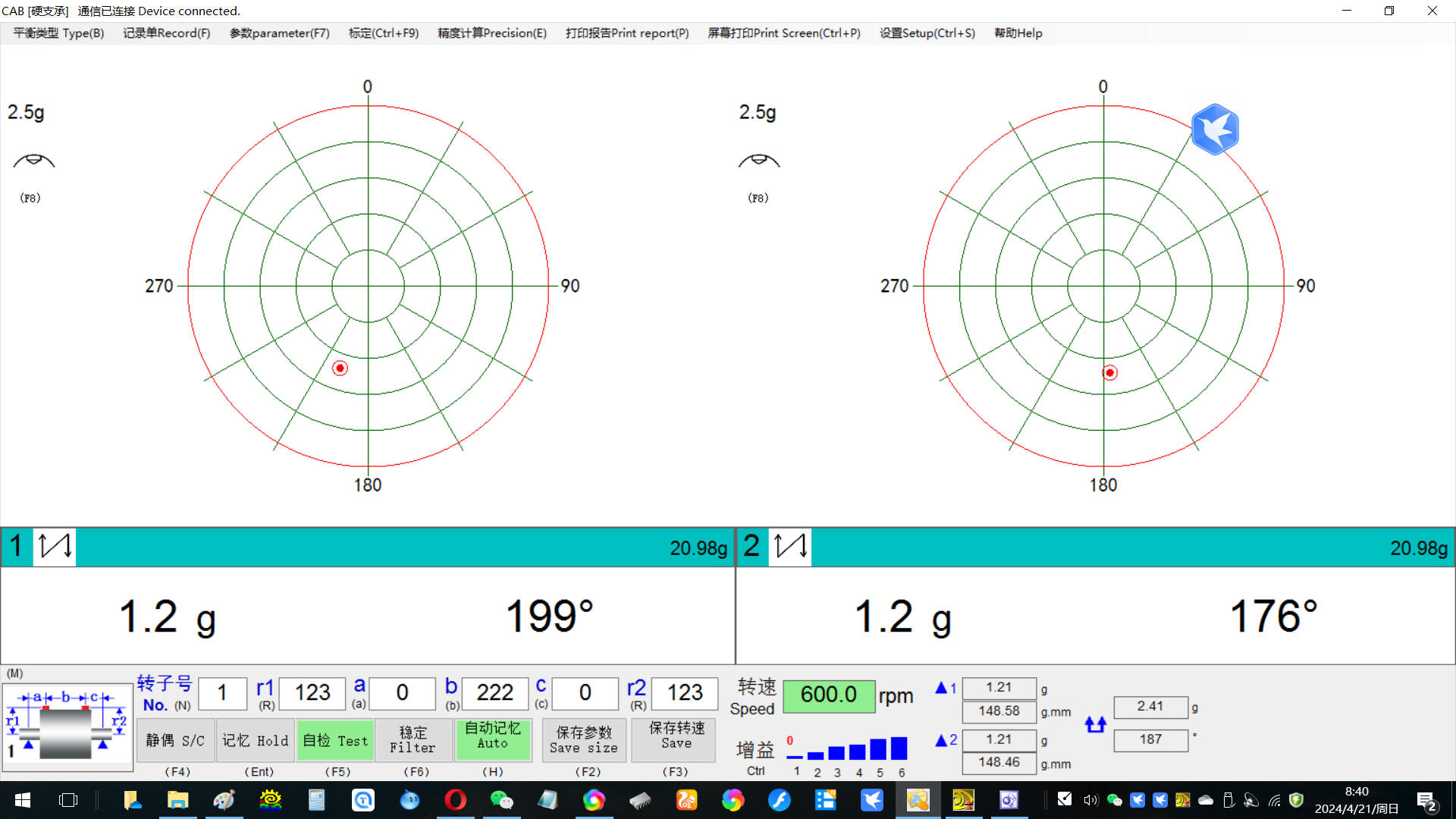

electromechanical tester uses industrial single-chip

technology and has a fast start-up speed, making it

especially suitable for factory work environments! The

technology that can be measured after turning on,

memorizing and stopping, can input and change the

automatic calculation result of the parameter, the

electrical measurement box has the data record of the

measurement result, and the measurement data sd card

records the function.

Our hard-bearing balancing machine is a

permanently calibrated hard-support balancing machine.

The rotors that balance different shapes and weights

do not need to be recalibrated. The size and angle of

the unbalanced values can be measured at a single start.

Address: Wanfeng Rd Dongmenwai Str. Xuanhua Hebei Province China

Post code:075100

Tel: +86 313 3175800

冀ICP备05002859号-2 冀ICP备05002859号-1

冀公安备13070502000109 冀公安备13070502000109

|