Special rotor balance process

Large

low-speed rotor balance:

Cement mill wind machine rotor

Must have a larger drag power, low speed measurement capability of the

electrical measurement system, a relatively clean electromagnetic

environment. For example: large mineral mill rotor (diameter greater than 4

meters) and so on.

YYW-16000A Balancing

Machine

(Low speed balancing machine, 7 meters large diameter) low speed

balancing machine below 80 rev / min, large diameter balancing machine

7000mm

Large-scale balance machine out of safety considerations, when used to

improve the operational safety considerations, do not shoot the forehead to

use, to be clear rotor operating parameters are not within the scope of

work! ! !

It's manual with a complete design parameter icon, it has more than one

parameter chart. These are the basics of how a technician using a balancing

machine must know it.

Features: Drive power to consider the user's rotor to determine the

specific circumstances, rather than ask the user how much power.

To get the user's maximum rotor parameters, balancing machine manufacturers

calculate how much drive power can meet the needs of the measurement.

Balancing machine drive power and measurement system has a

cross-parameter, that is, measuring speed, and drive speed.

If your measuring system starts measuring at 200 rpm then your drive system

will meet this requirement.

For example: A fan of 2000kw If the working speed is 500rpm, then it

runs to 200rpm when it is 128kw.

While 140rpm is 43.9kw

Therefore, a measurement system that can measure low speed is a

prerequisite for a large fan balancing machine.

1 drive power larger.

2 Measurement speed is low 80 rpm Start measurement

3 larger working diameter (fan features).

4 Heavy duty balancing machine (greater than 10 tons) must meet the maximum

contact pressure conditions of the workpiece axis (to meet the positive

pressure direction of the elastic working range, in order to avoid contact

with the surface fatigue damage). That is, the work of the wheel diameter

must be large enough to ensure that the contact area is large enough.

Otherwise it will hurt the customer's product axis (fatigue crush, crush

with plastic deformation).

5 Overload capacity larger (twice), the overall stiffness of the cast steel

measured, the linearity to maintain more than twice the maximum mass.

6 has a braking function, especially a large balancing machine. Large rotor

inertia parking will continue around 20 minutes. Braking function can be

within 1-3 minutes parking.

7 large-scale balancing machine with multi-stage gearbox (4-5 deceleration

of 6 times or more)

The company is located in:

Small

fan rotor balance

Axial force generated when the fan rotor rotates, so the use of belt-driven

mode balance will produce axial force, the balance of interference difficult

to meet the requirements of precision. At the same time the efficiency of

the process is relatively low.

YYW-30-type balancing machine is the latest design and manufacture of a

high-efficiency small size balancing machine.

This machine is mainly to solve the problem of dynamic balance of small fan

to meet the production specifications of the factory.

The special small-size universal joint structure solves the problem of the

universal joint of the small rotor.

YYW-30-type balancing

machine

The company is located in:

Very small high-speed rotor balance:

Electro-measurement technology that requires very low electromagnetic noise,

as well as soft support small balance machines. Such as dental drill rotor,

small DC motor rotor and so on.

RYQ-5-type

soft-bearing precision balancing machines

The measuring mechanism of this machine is the same as that of the

old-style soft support balancer, which is completely redesigned and improved

from mechanical structure and electrical measuring system, and the

durability of the machine is greatly improved.

Support: Soft support structure is simple, stable performance. The use of

speed sensor, no lateral sensitivity, less demanding on the limit, making

the operation requirements simple and quick. The structure is compact, solid

and reliable, and its mechanical model is reasonable. The actual imbalance

of the rotor can be truly reflected by the support frame and the sensor. And

this is exactly the most basic part to ensure the measurement accuracy of

the balance machine. Balance can be intuitive to use hand to feel the state.

Small rotor balance is more troublesome, soft support mode is the closest

operating mode, almost working speed measurement. Therefore, high-precision

balance is best to soft support mode.

In recent years, the market decline of the soft support balancer is due

to the high structural failure rate of the machine. Now we have designed an

ultra-low failure rate rack.

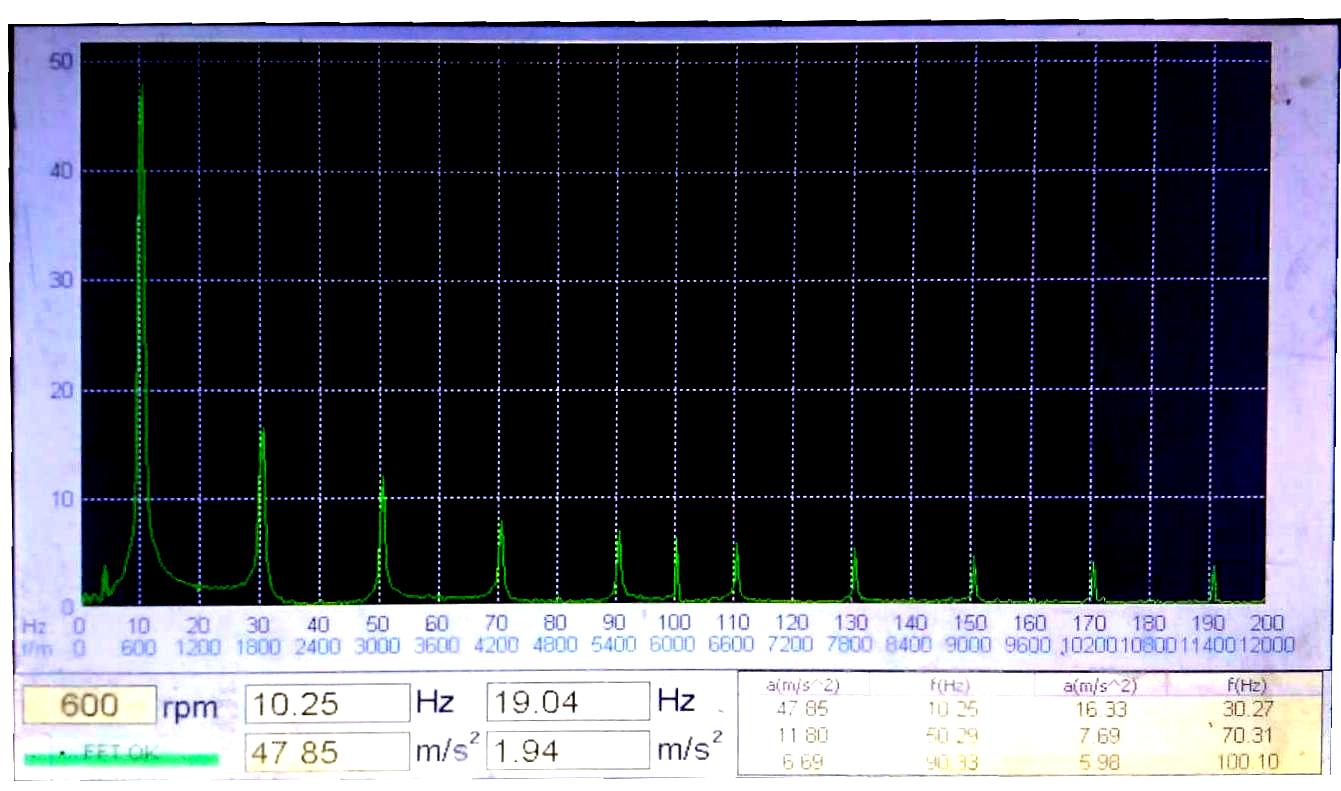

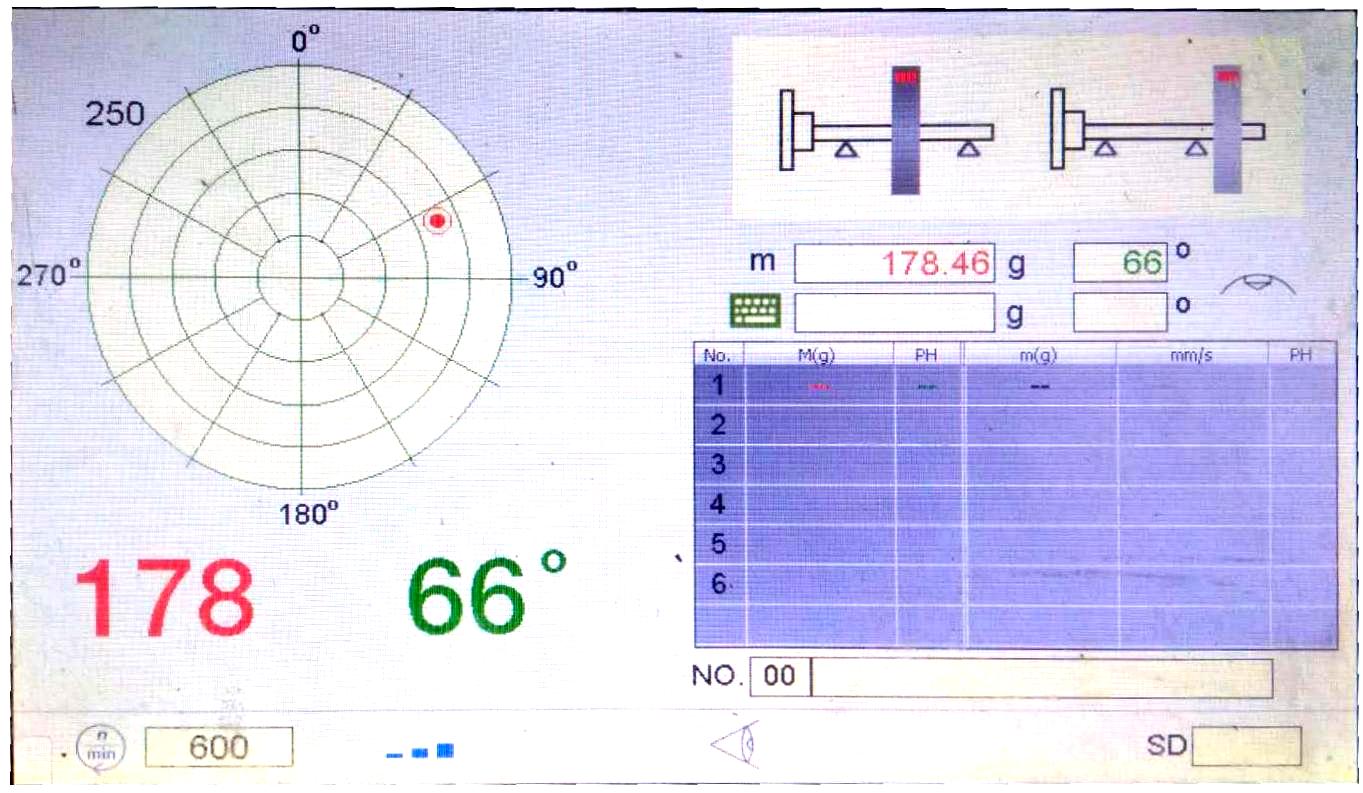

Site balance:

Some rotors can only be balanced on site, requiring a field balancer, as

well as a skilful operating experience of the field balancing process. For

example: Do not disassemble the fan rotor. Test Method Reference ------

Mechanical vibration reasons

Multi-section drive shaft balance:

Need to have multiple signal switching electrical measurement system, a

number of swing frame. Due to the advantages of big torque of face teeth,

many trucks now use such a structure of the drive shaft, but the end tooth

structure should not be consistent concentricity, so the use of a single

balance can not solve the balance of the problem, only imitation The balance

of their working conditions before they can solve the vibration, rotten

rubber sleeve (intermediate support bearing) problem.

Five pendulum four-axis coupling, which is to solve the "face gear drive

shaft" the only way to balance the issue.

High-speed rotor balance:

Need flexible balance technology, electrical measurement system using the

influence coefficient method to solve. For example: chemical industry with

high-speed compressor.

Equivalent block rotor balance:

Need to have a multi-faceted electrical measurement system, at the same

time can be fixed vector solution. For example: engine crankshaft balancing

process.